As a Manufacturing Engineer at Velatron Technologies, a large part of my role is to head up projects that aim to create efficient manufacturing practices as well as designing methods for building custom electronic components. These are some of the more prominent project I took on while at the company.

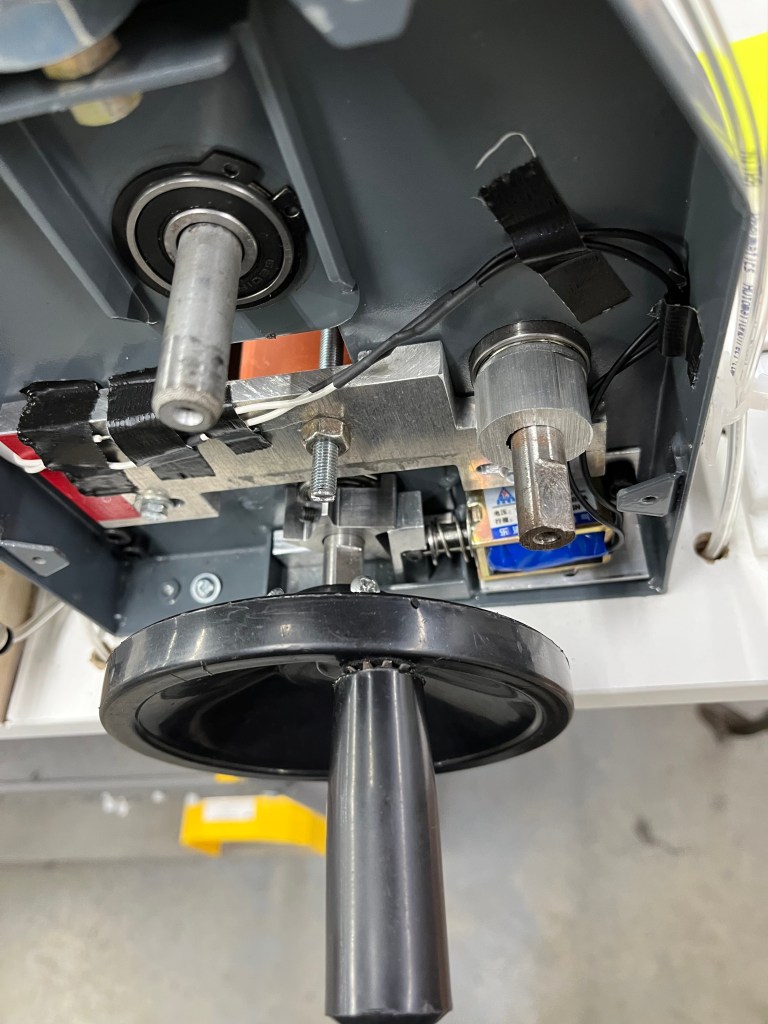

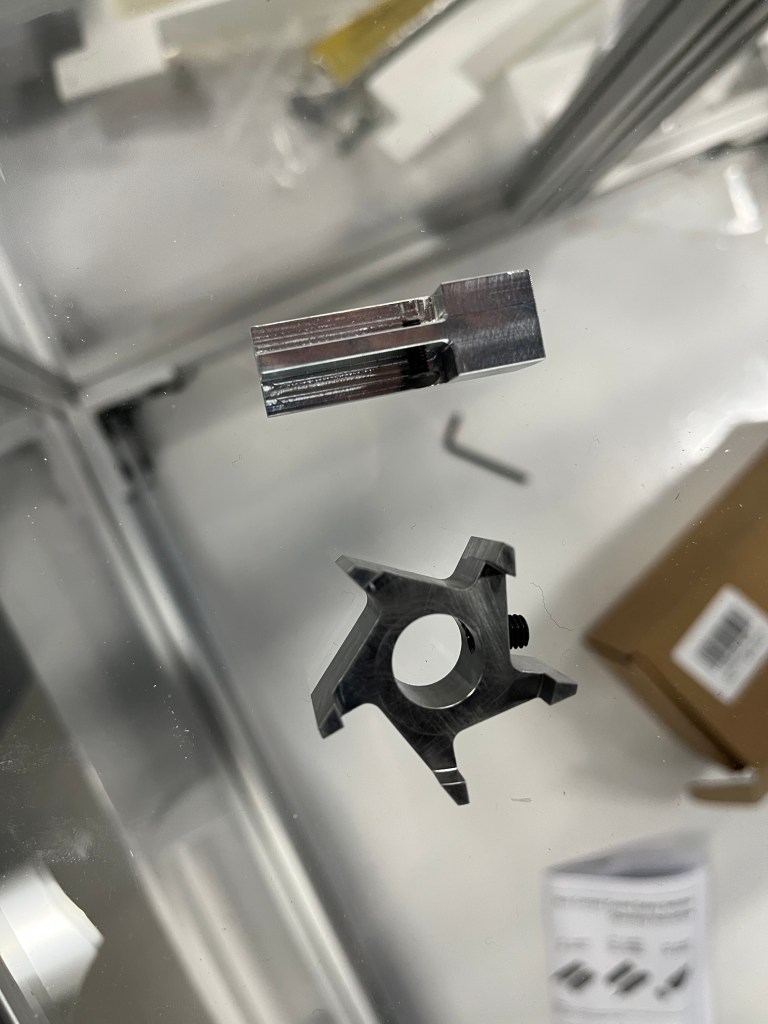

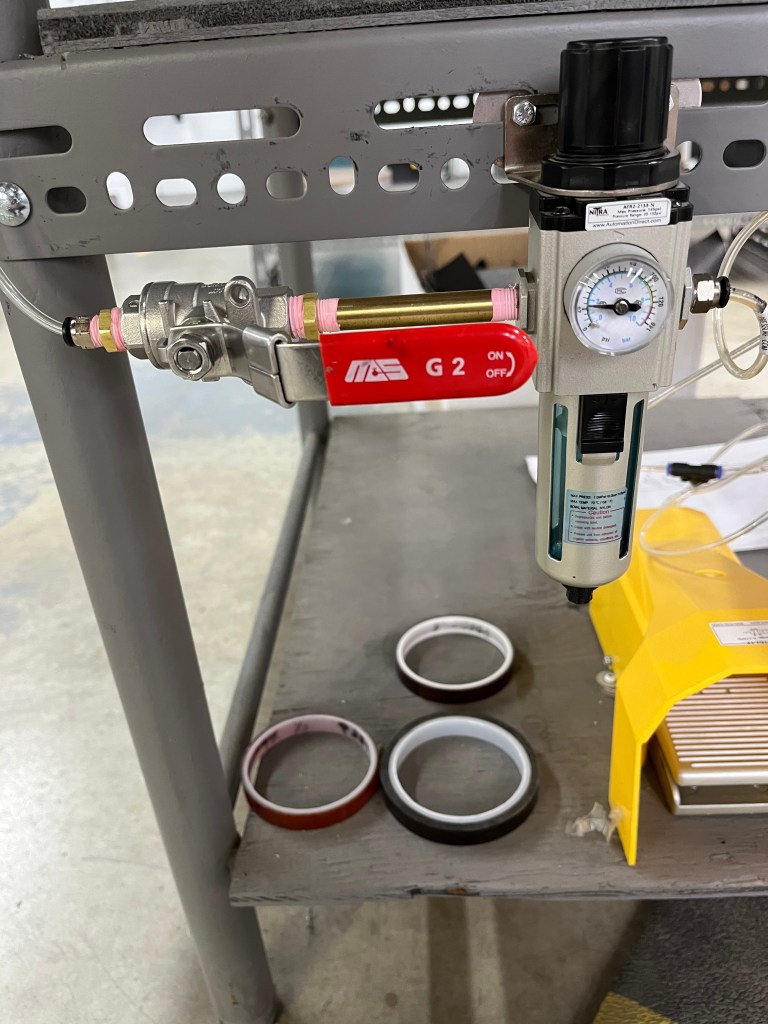

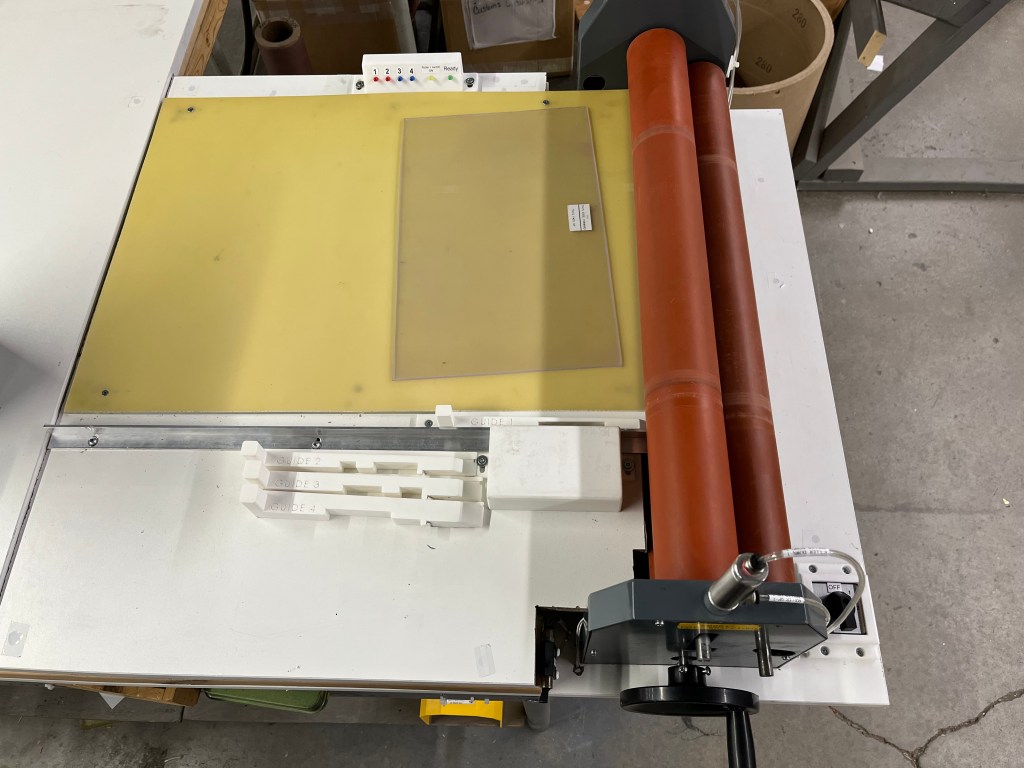

Antenna Winding Station

Sept 2025 – Dec 2025

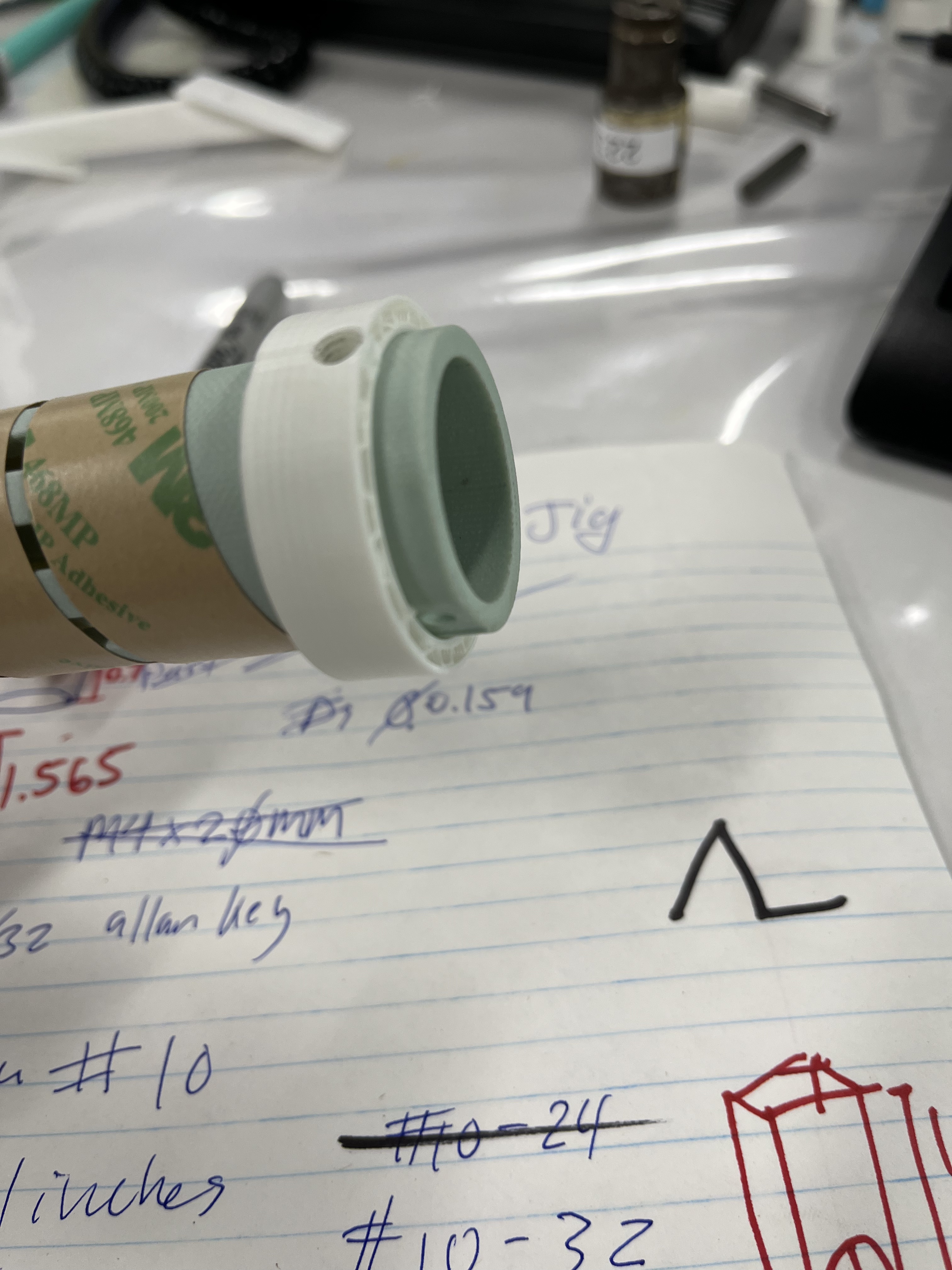

This continuous improvement project converted an existing pneumatic roller machine into a reliable, multi-purpose antenna winding station for production use. I upgraded the pneumatic system, designed custom tooling and fixtures, integrated an electrical warning/braking system and developed precision cutting jigs achieving tolerances of ±0.008″. I also established the manufacturing technique and step-by-step process for producing the parts with clear documentation and defined next steps for future co-op students. The results are a machine that is production-ready with further improvements underway to support integration into high-volume manufacturing.

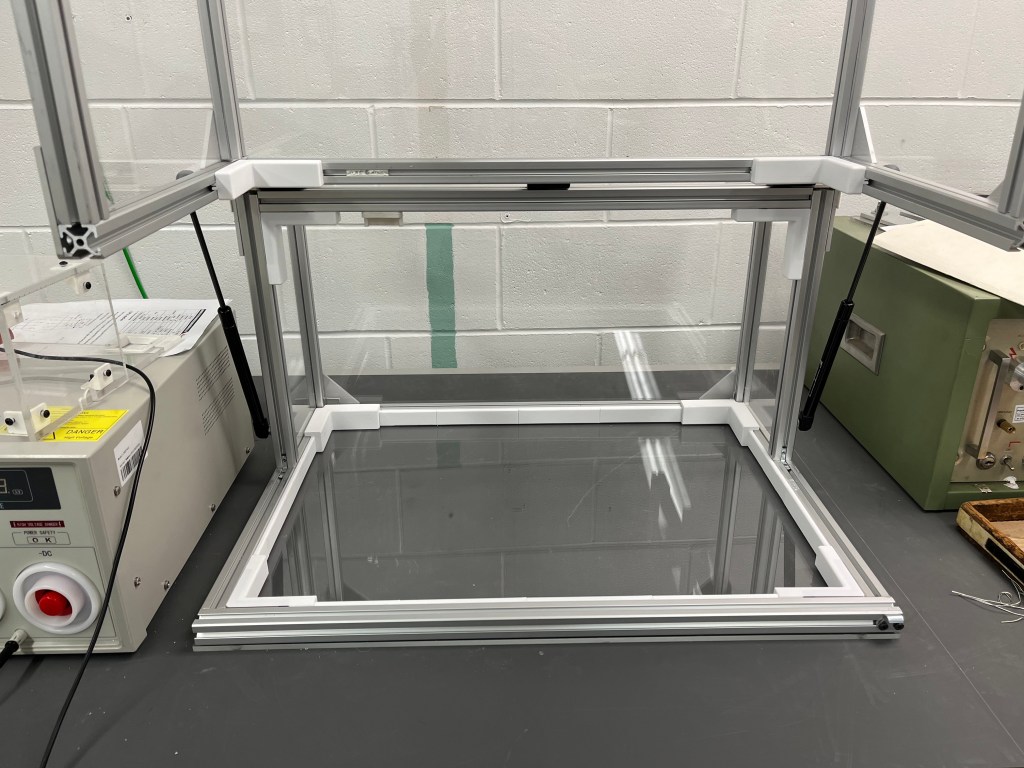

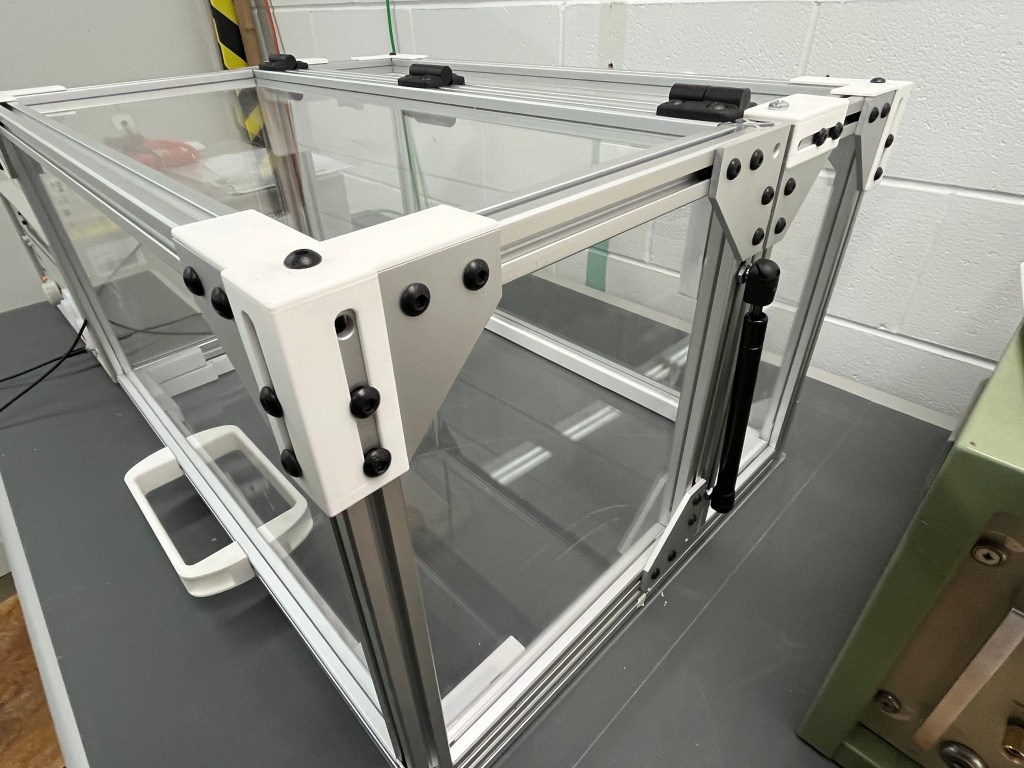

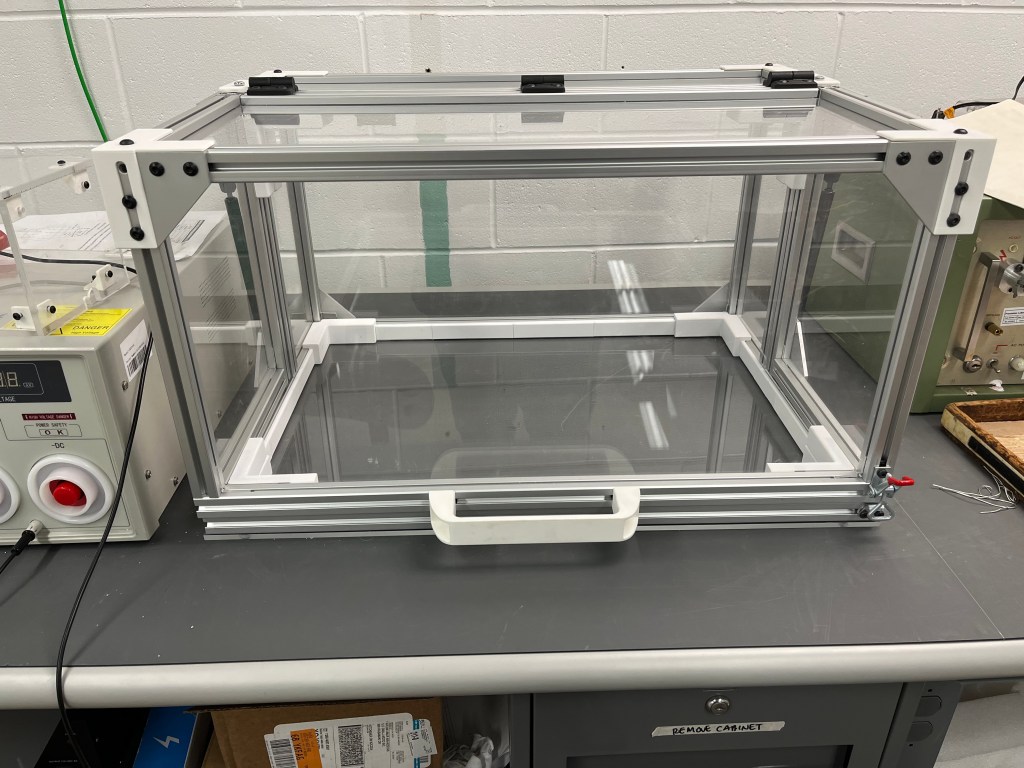

HiPot Testing Enclosure

Oct 2025 – Dec 2025

I designed and built a high voltage safety enclosure for hipot testing intended for repeat use in a production environment. Throughout the project, I coordinated closely with other engineers to integrate the enclosure into a broader electrical safety box system, ensuring seamless compatibility with existing controls and safety infrastructure. The work involved researching safety requirements, sourcing materials and independently designing, machining, and assembling the enclosure. I integrated electromagnetic safety interlocks, gas shock mechanisms for controlled opening and closing as well as 3D printed a PC FR insulating base to improve electrical isolation and overall safety. The final enclosure is rated for electrical testing up to 20kV and is actively used in manufacturing It is delivering a production ready solution that improves operator safety and standardizes high voltage testing procedures.

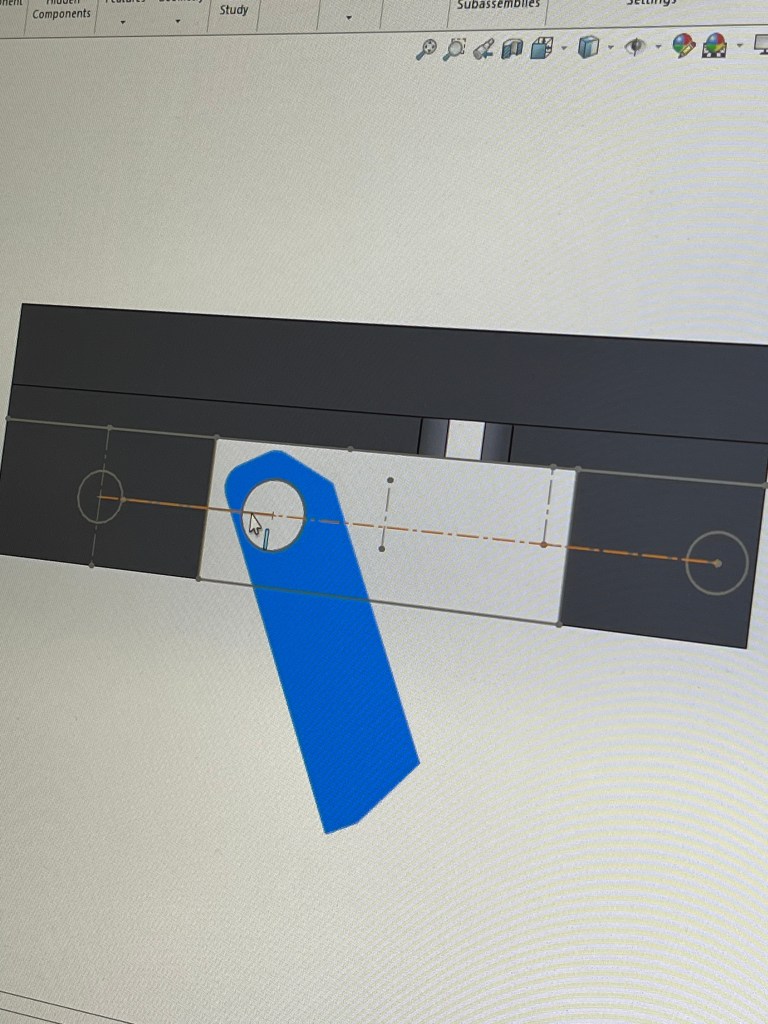

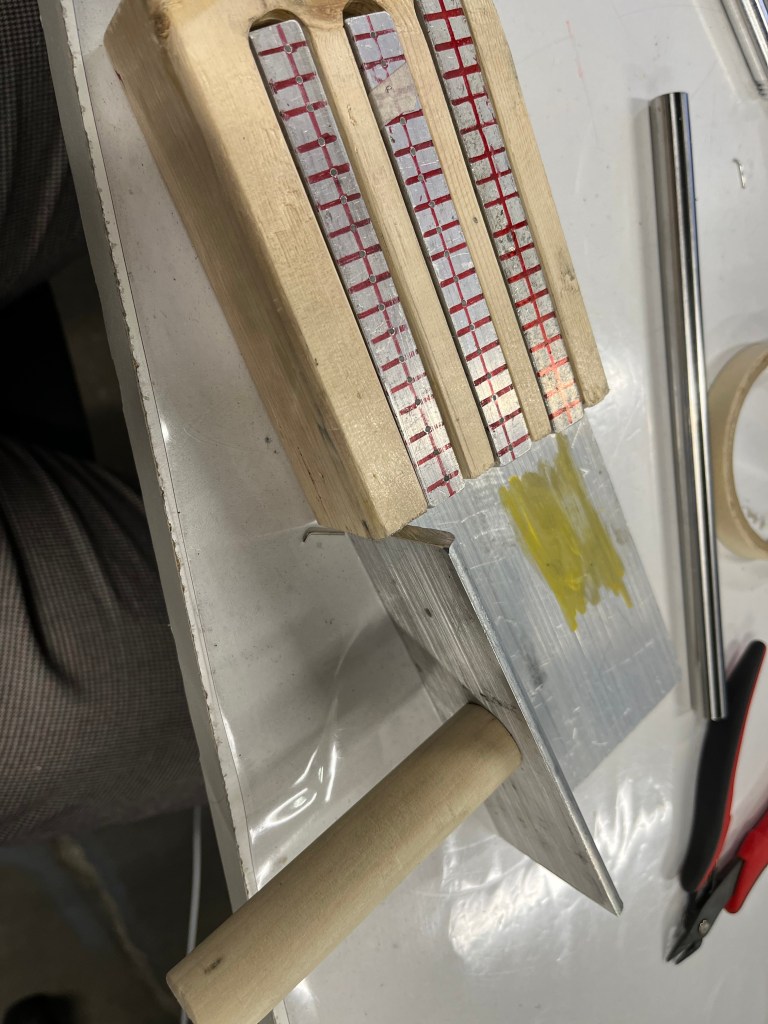

Tube Guillotine

Feb 2025 – Apr 2025

I developed a high-efficiency tube-cutting “guillotine” designed to streamline the material preparation process, particularly for high-volume workflows. The system is tailored to improve speed, accuracy, and ergonomics for the operator.

The setup features a spring-loaded handle that provides quick recoil for faster cycle times, reducing strain and increasing throughput. I machined a durable aluminum baseplate that both supports the entire jig and provides a smooth channel for feeding tubing into the cutting zone. A custom-machined blade, sharp enough to cut through plastic tubing cleanly, ensures precise and effortless cuts.

To facilitate workflow, I integrated a drop system that channels cut tubing directly into a basket below, minimizing manual handling. The jig also includes a transparent plexiglass top, which not only protects the user but allows for tubing length measurements to be marked using dry erase markers—making it easy to switch between sizes as needed. An adjustable stopper ensures repeatable, consistent cuts every time.

This tool has optimized the tube-cutting process, improving speed in material prep operations.

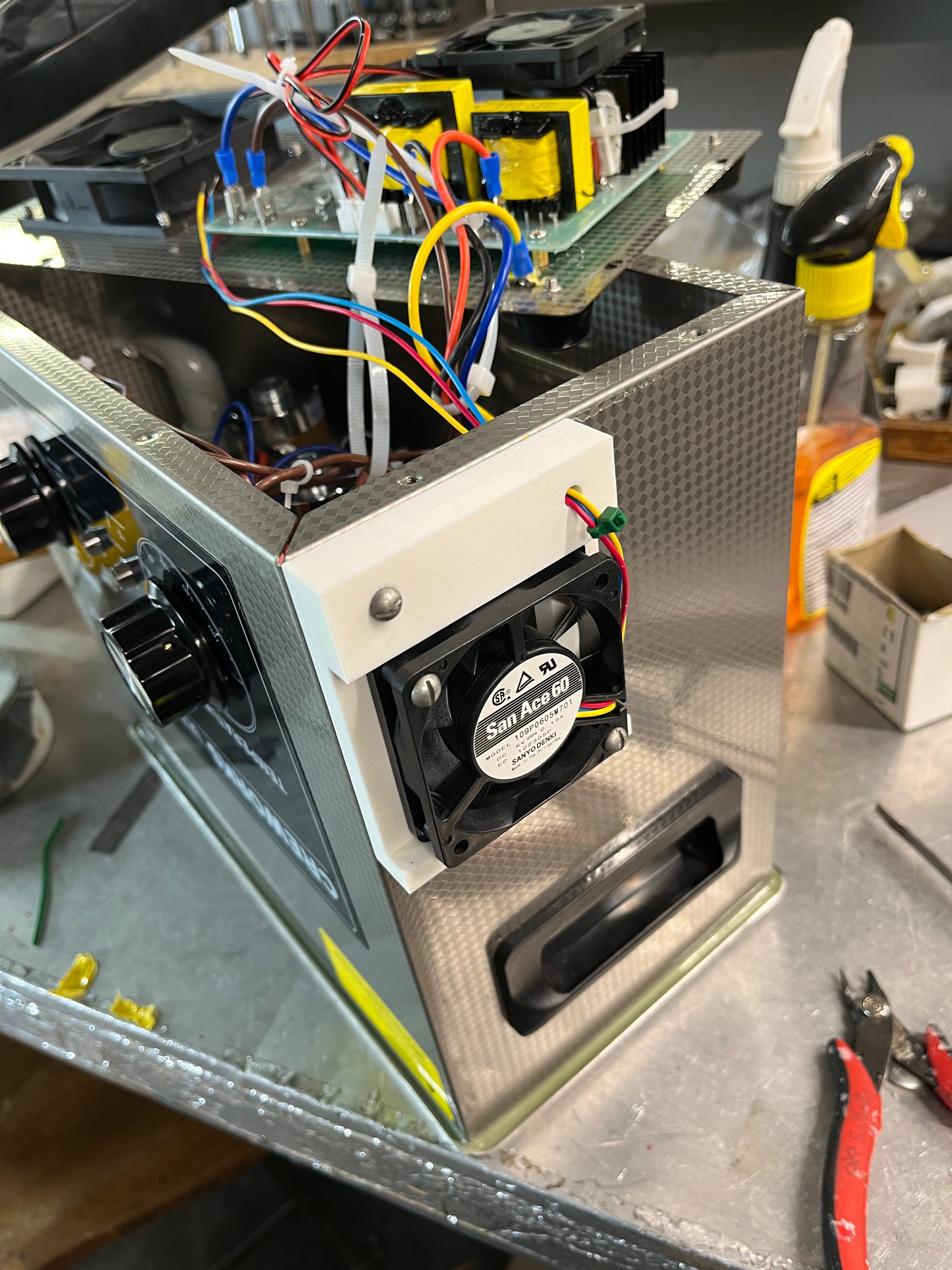

Machine Ventilation

Apr 2025 – Apr 2025

I designed and implemented a custom intake ventilation system to address a recurring overheating issue in a machine that typically requires repair or replacement every six months. To improve airflow and internal cooling, I engineered a solution that activates only when the machine is in use, maximizing efficiency. This system includes a fan that directs air into the machine’s internal components, helping to regulate temperature and reduce thermal stress.

To install the system, I drilled into the stainless steel frame and designed a custom mounting bracket to securely hold the fan in place. The bracket was 3D printed to fit the machine’s dimensions precisely and ensure long-term stability under operational conditions.

The setup is currently in operation, and we are monitoring its performance to evaluate its effectiveness in improving ventilation and potentially extending the machine’s lifespan.

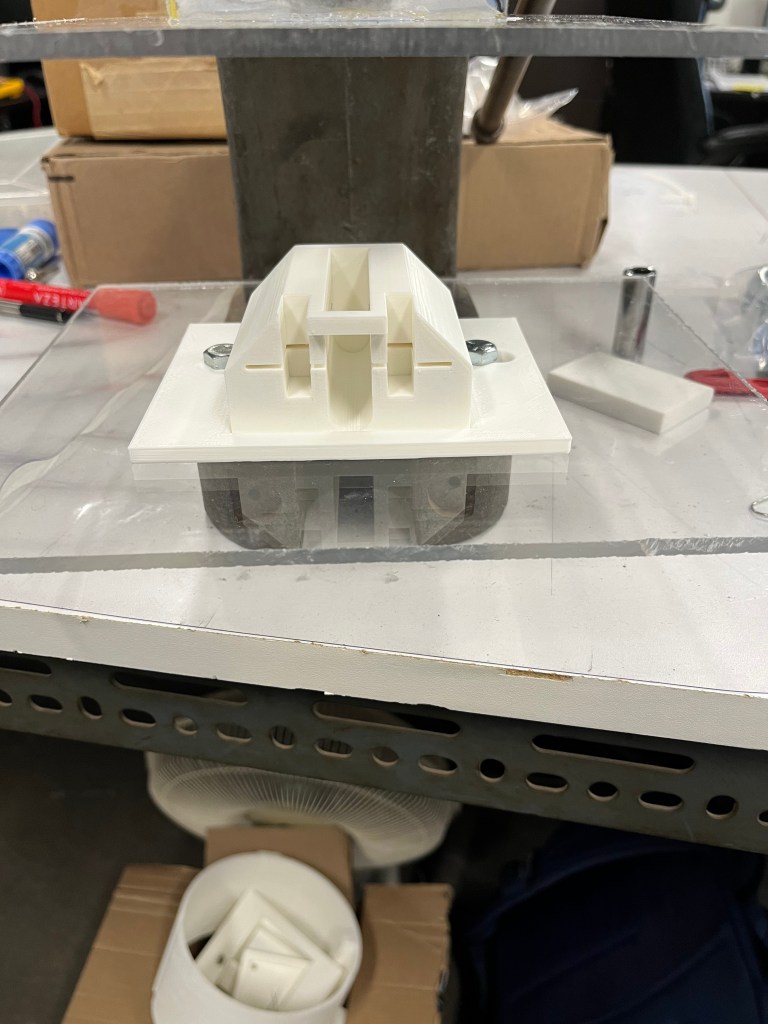

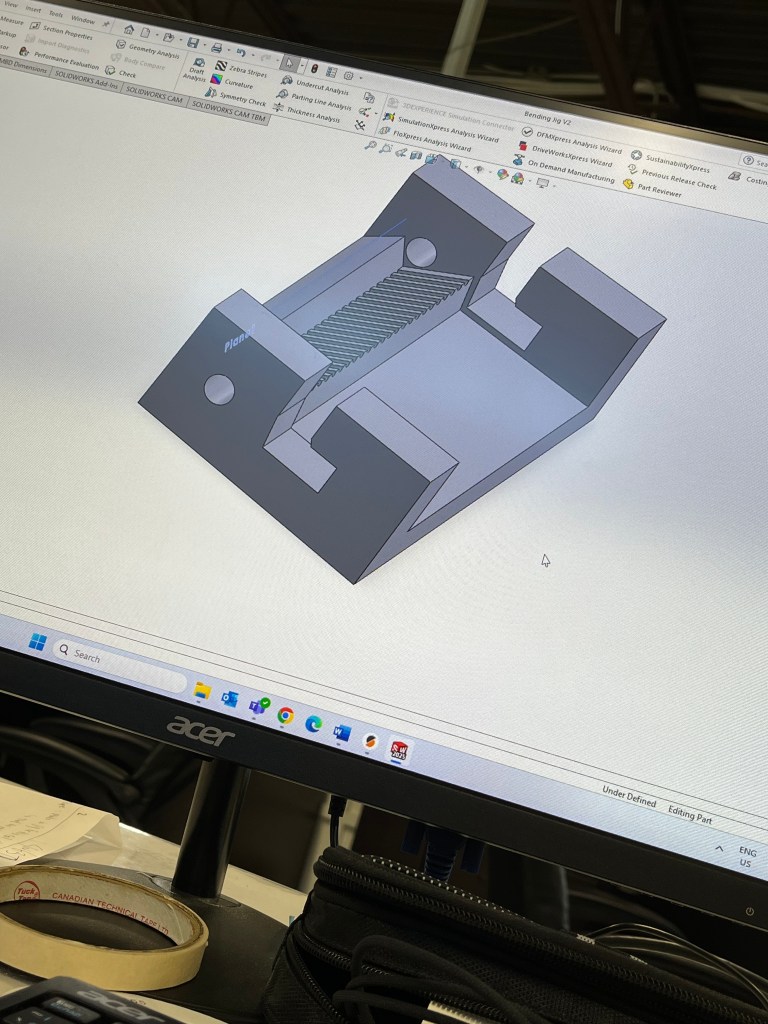

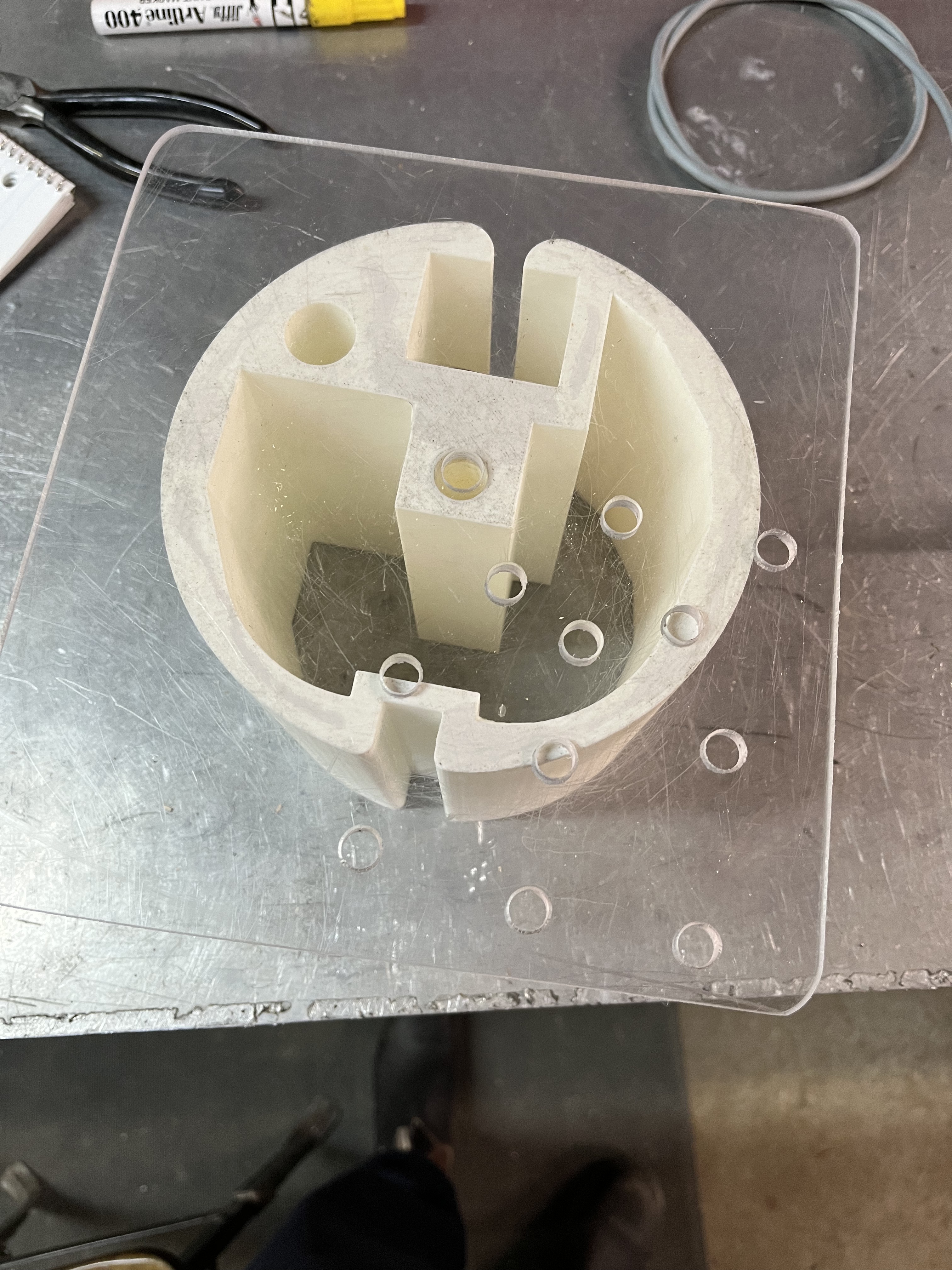

OMEGA Wire Press

Mar 2025 – Apr 2025

I was initially tasked with developing a method to mass-produce 90-degree bent wires for a large production order of over 20,000 units, each requiring two bent wires for manual coil finishing. After several weeks of prototyping and testing various bending methods, it became clear that all options were inefficient at scale. Upon reviewing the full coil finishing process with the engineering and production teams, we discovered that the workflow hadn’t been optimized for high-volume production in over 15 years.

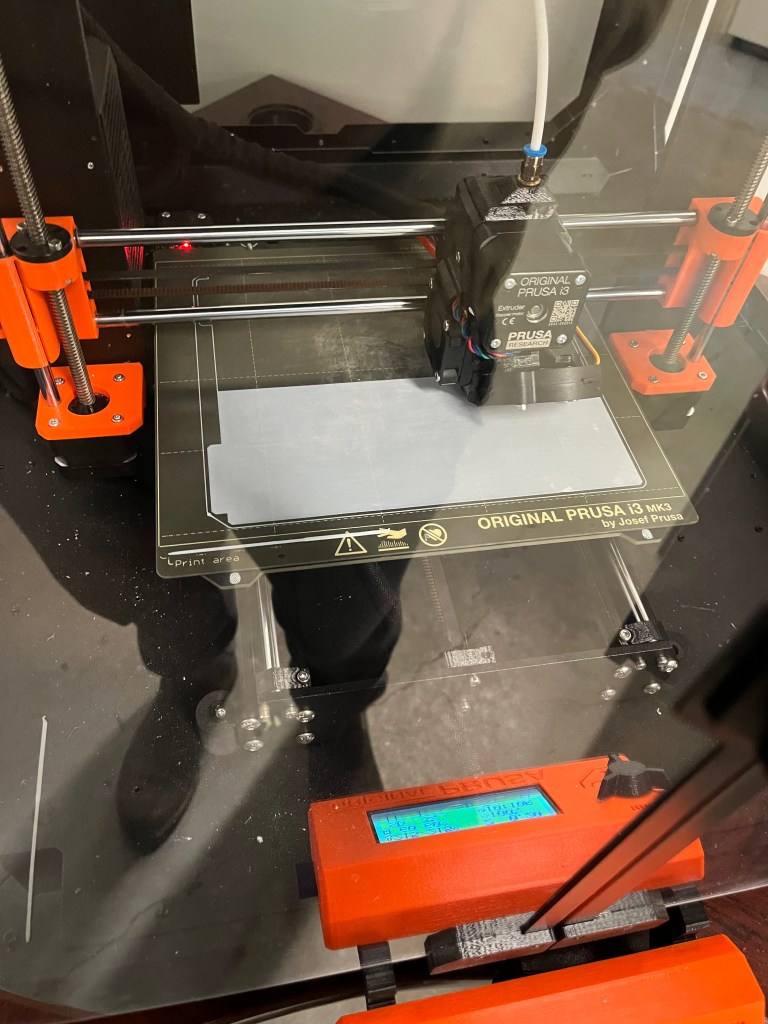

Working closely with the team, I proposed a redesign of the process by introducing an omega-shaped wire bend, which allowed for faster coil finishing and cutting after forming. I was given lead responsibility for developing a method to produce the new shape and designed a press system inspired by cookie-cutter manufacturing. Using an old lever press, I built a prototype jig from 3D-printed PLA and plexiglass, later finalizing the design in ABS plastic for durability.

In addition to designing the jig, I performed a cost and waste analysis to ensure the new method was viable for production. The final setup reduced coil finishing time from 5 minutes to 3 minutes per unit, significantly improving workflow efficiency and easing the burden on the coil finishing team, which had previously been the primary bottleneck in the process.

-

Final Bending Jig

First Iterations of the 90-degree Bending Jig and First Attempt at Omega-Shaped Bending Jig

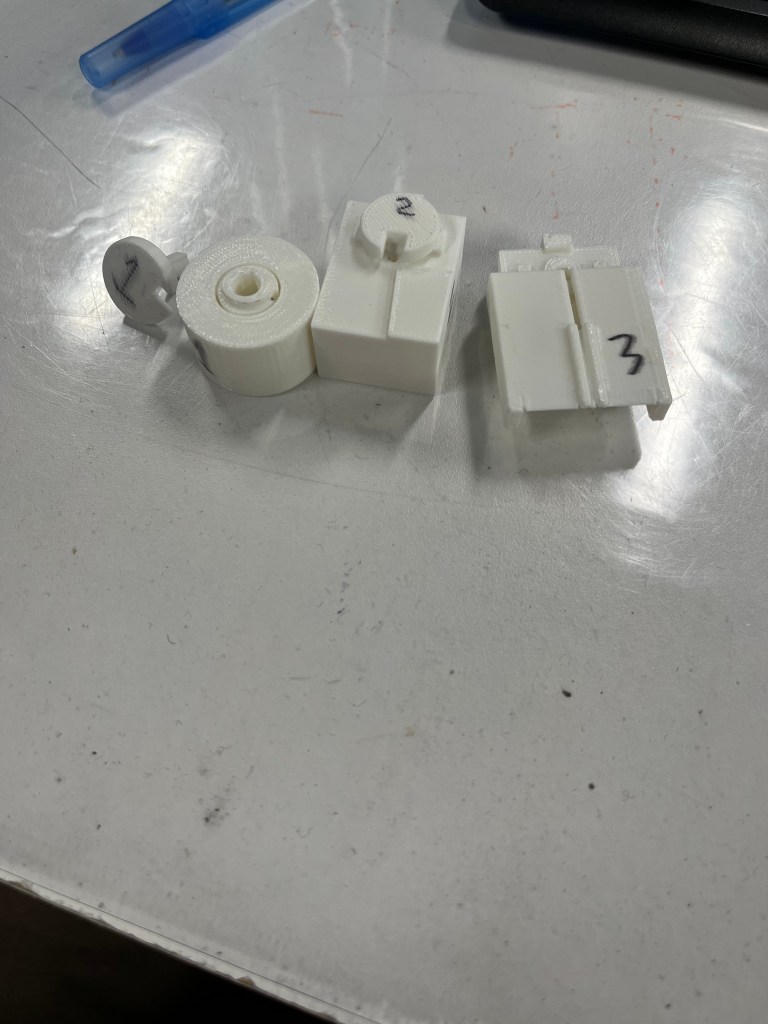

Spiral Coil Jigs

Mar 2025 – Mar 2025

I was tasked with developing both the process and tooling required to create a precise wire winding used in a medical machine application. The project involved working from general drawings provided by the customer, which included extremely tight tolerances. To meet the requirements within a one-week timeline, I prototyped a variety of jig designs to achieve the specific bends needed. After evaluating different configurations, I finalized a three-jig system that accurately forms the wire to the required shape. This process is now the standard method used for producing these components. I also revised the original drawings, adjusting the tolerances to make them more feasible for production while still meeting functional requirements, and submitted the updated version to the customer for approval. The final solution balanced precision, repeatability, and efficiency under a tight deadline, ensuring a reliable manufacturing process for a critical medical device component.

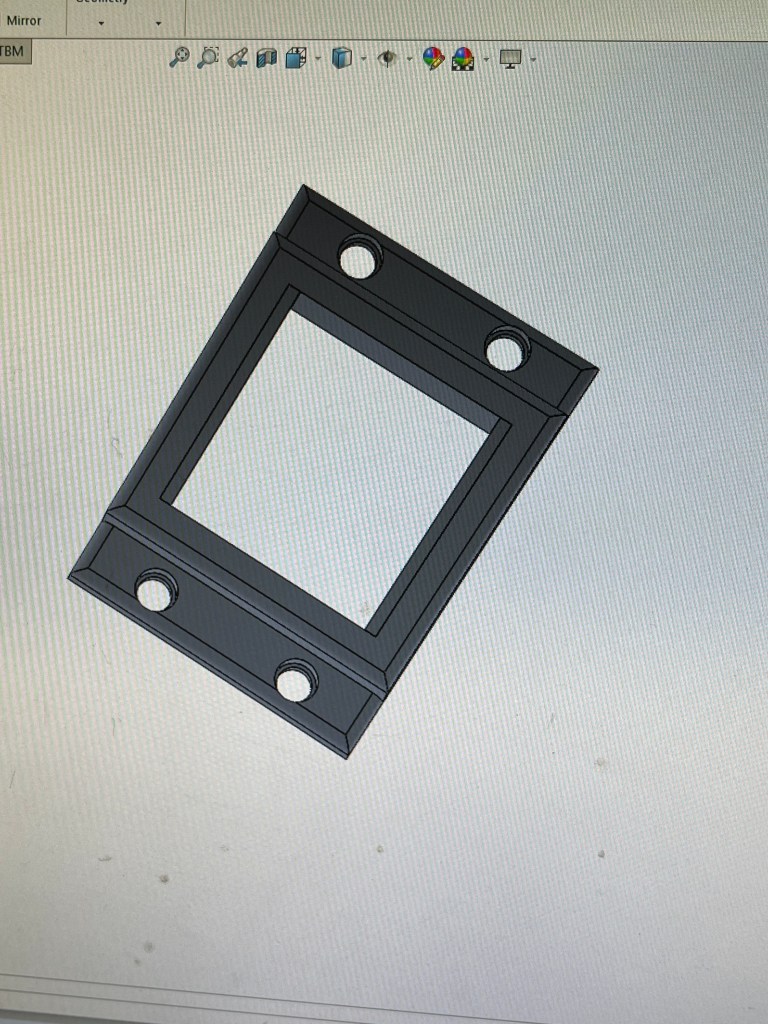

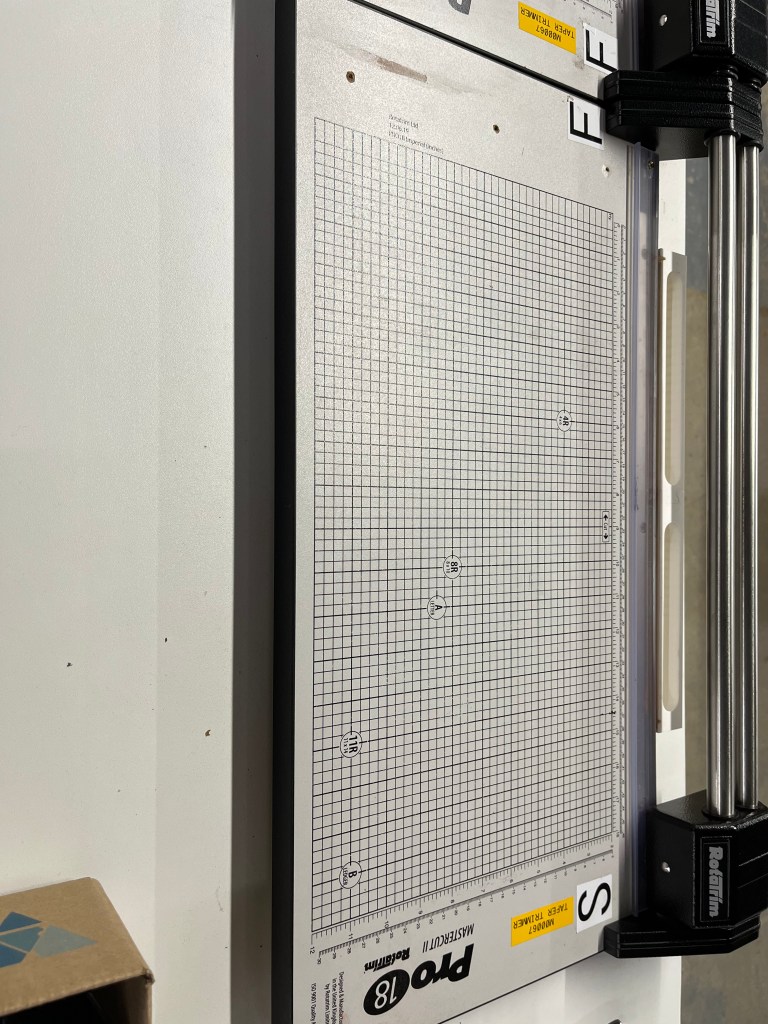

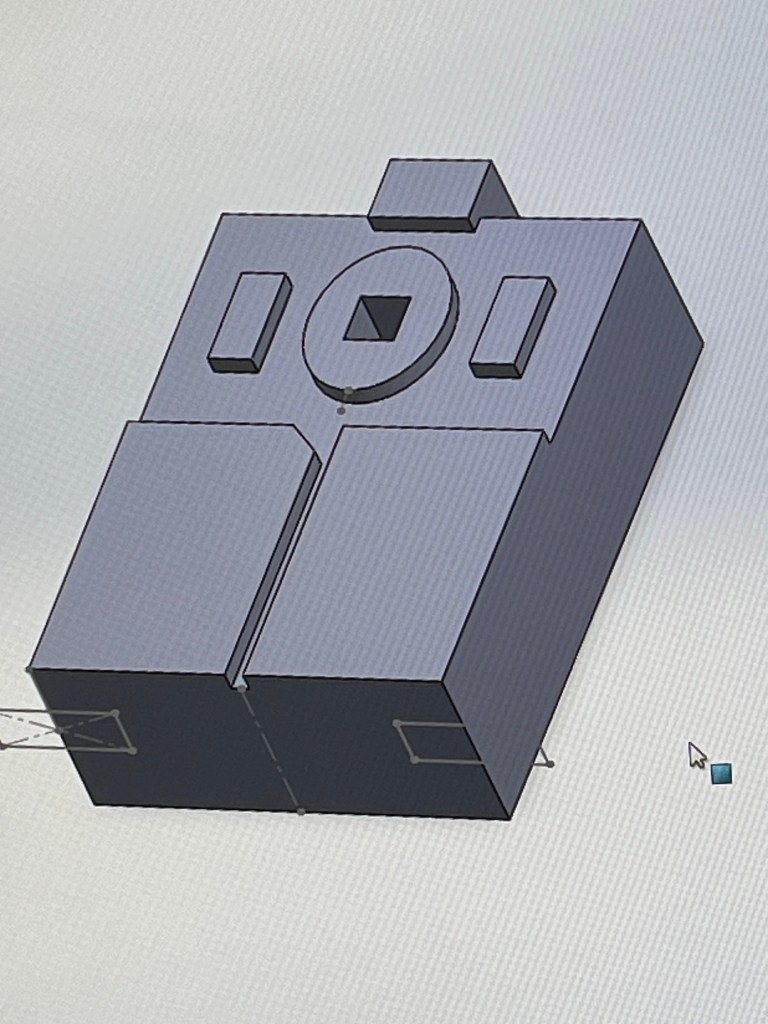

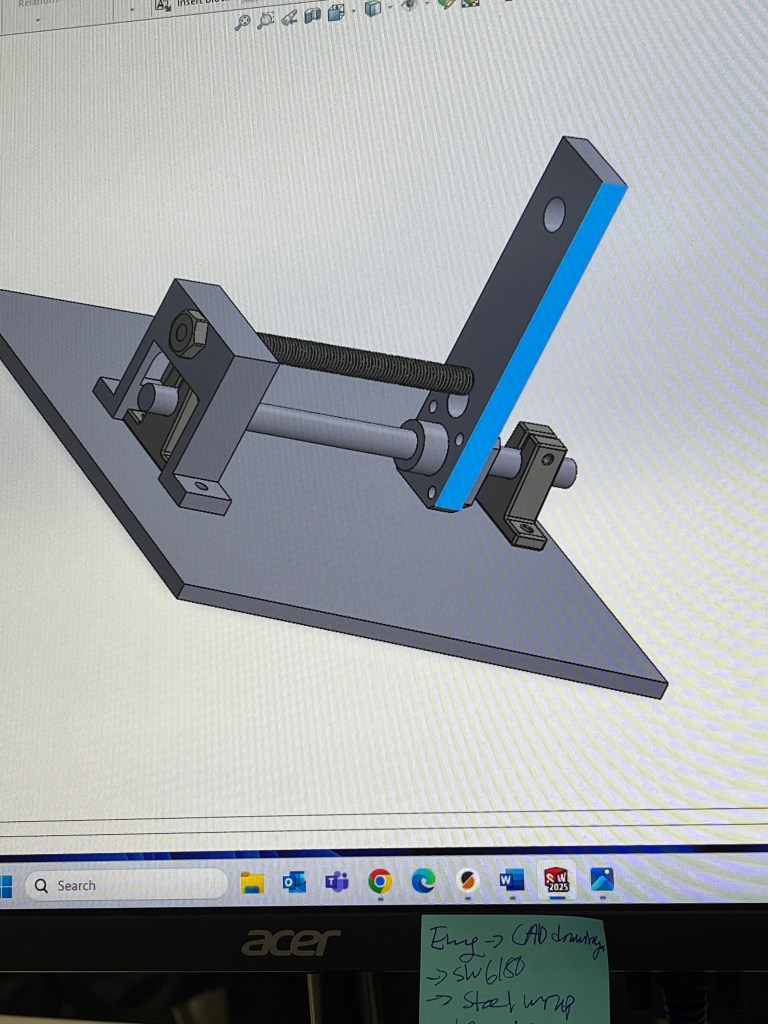

Conveyor Belt Tensioner

Mar 2025 – Mar 2025

For one of the company’s projects, we developed a custom conveyor belt system to support the manufacturing of a specialized part. My role in this project was to design and build a belt tensioner that would keep the conveyor tight and running smoothly throughout operation.

To keep costs low, I salvaged parts from an old, broken machine and found nearly-new linear ball bearings and steel rods that could be reused. I designed the tensioner components in SOLIDWORKS and created an assembly, then 3D printed prototype parts to test fit and function with the salvaged components. After reviewing and confirming the design with one of the engineers, I sent the final CAD files to a machinist, who manufactured the parts in steel for durability and long-term use.

Although the conveyor belt will not be in-use until after the end of my co-op term ends, the parts seemed to work in the overall assembly and tests.

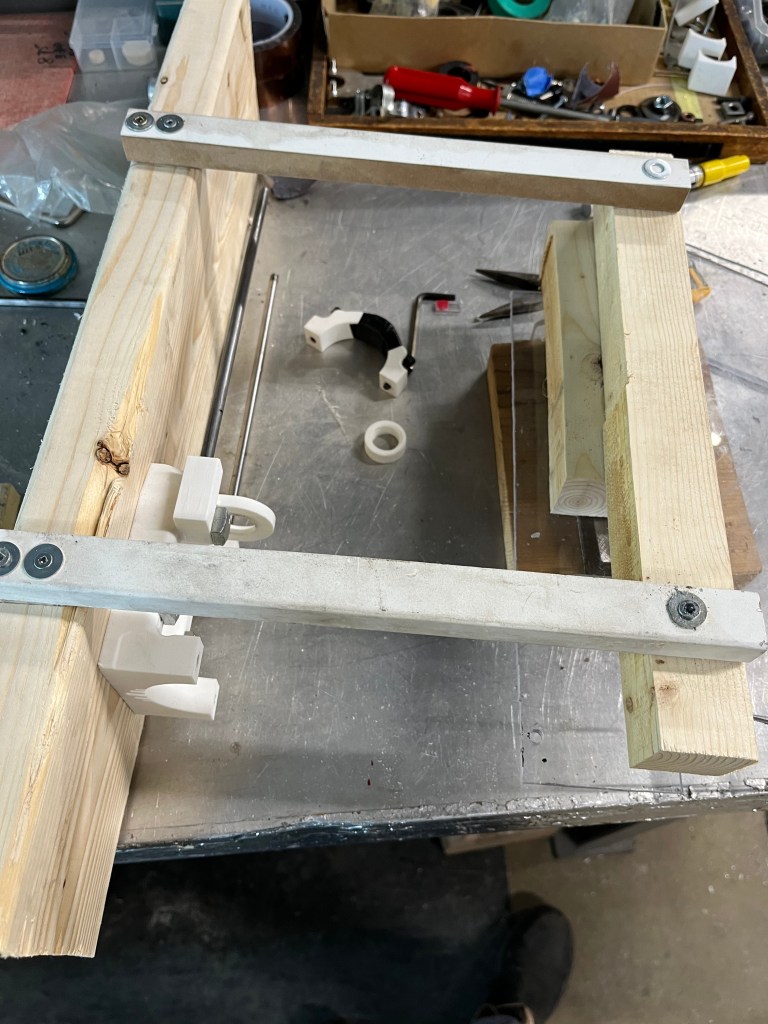

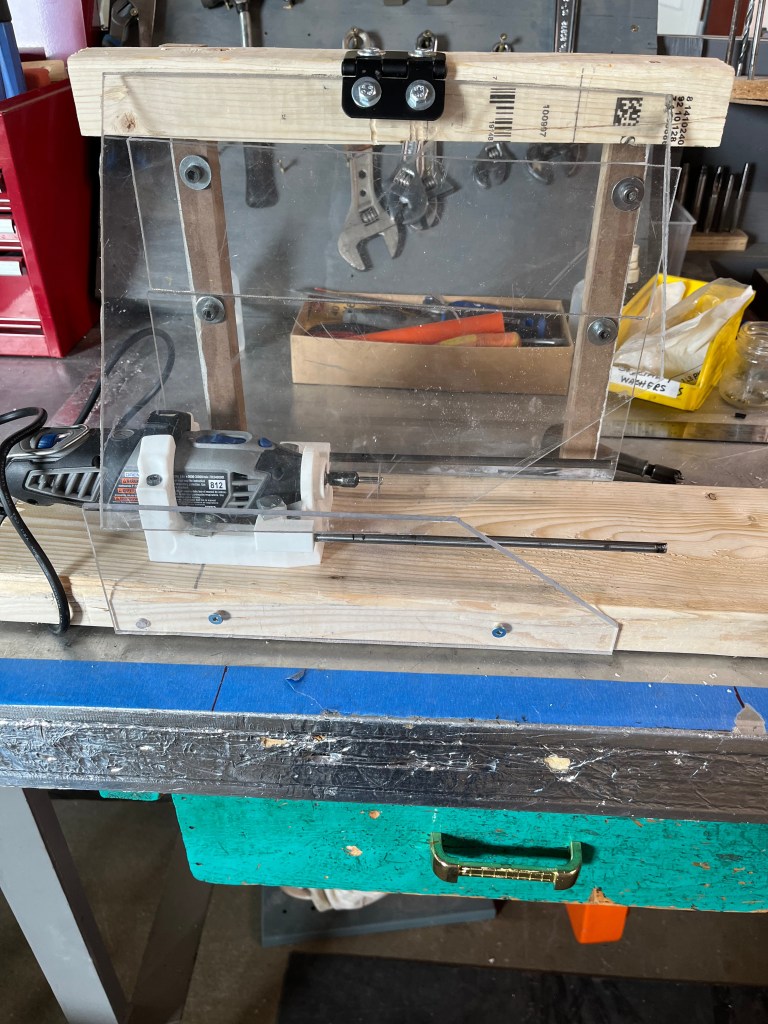

Horizontal Dremel Grinder

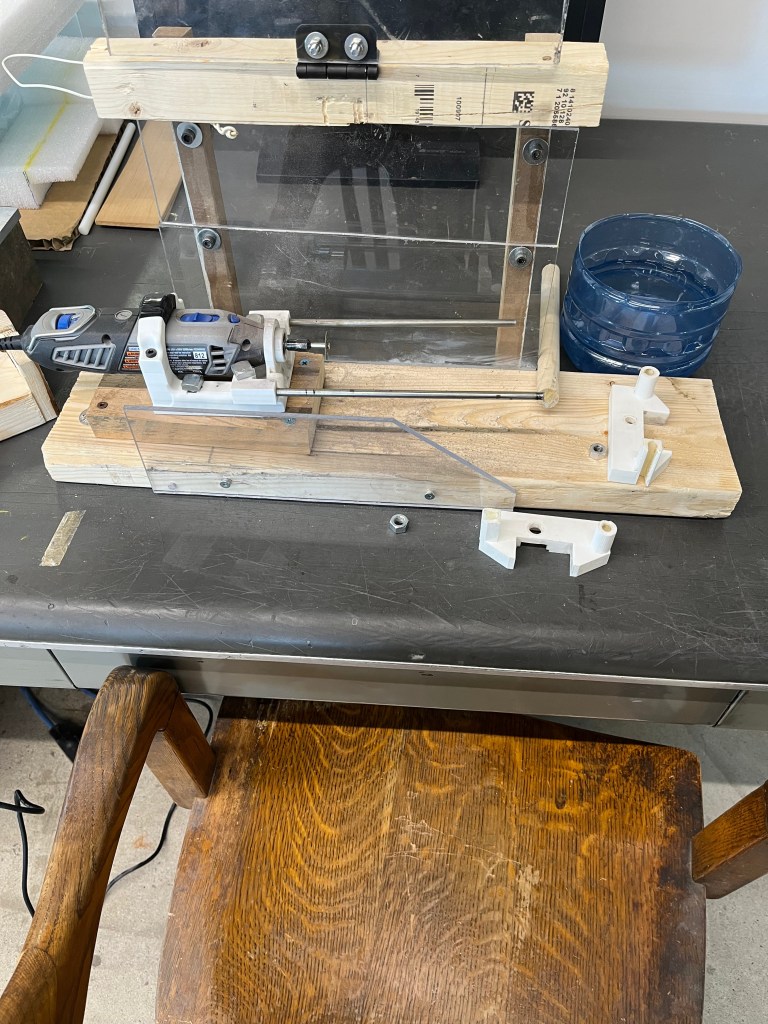

Feb 2025 – Mar 2025

As part of a high-priority project, I was tasked with prototyping methods to precisely remove excess tinned wire from a part, flush to its surface. The tolerances were extremely tight and the wire was located in a difficult-to-reach area. This made it impossible to use conventional cutting tools or machines without risking damage to the surrounding components. The solution needed to be both accurate and repeatable for production workers.

After collaborating with the engineering team, we decided that grinding the wire down was the most viable option. I proposed using a precision tool like a Dremel combined with a custom jig that would allow the wire to be fed in and stopped just before touching the surface. This would allow us to stay within a 0.1mm tolerance with minimal damage.

After weeks of iteration, I built a setup that could reliably grind the wire down to spec. The setup was assembled using a combination of 3D printed components, scrap wood, and other leftover materials like plexiglass. It proved to be a cost-effective and functional solution for producing the initial sample parts for the customer.

However, repeatability for mass production was still a challenge. I’ve laid out documentation and suggestions for future improvements into higher volume production.

Chemical Cup Holder

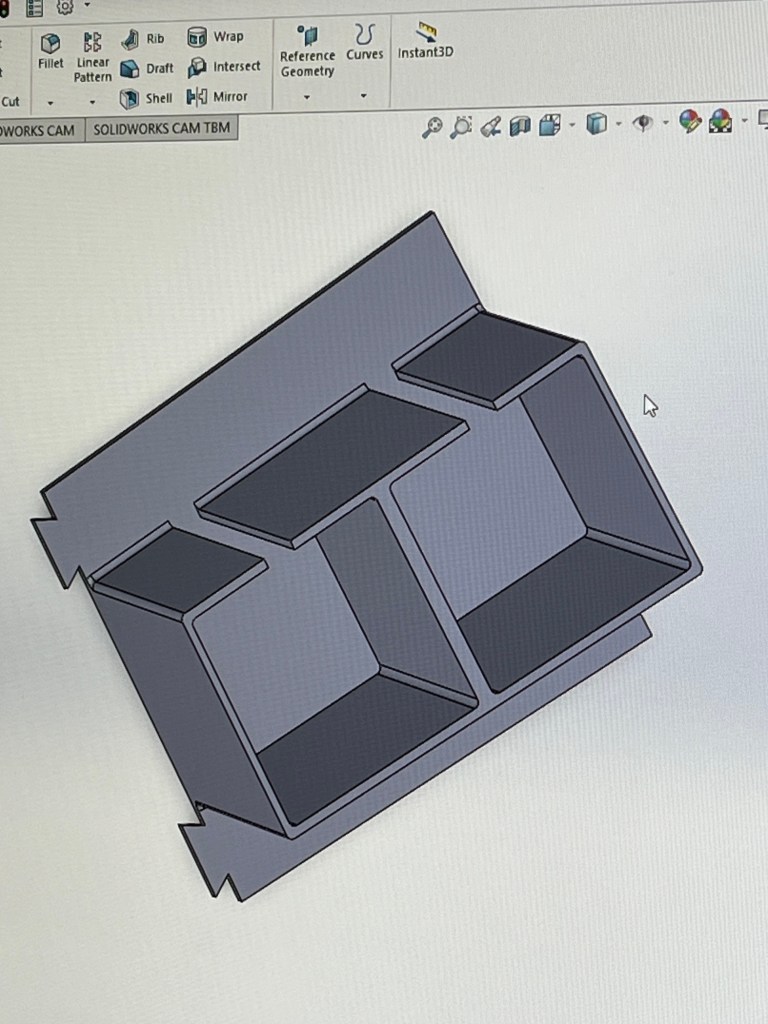

Jan 2025 – Jan 2025

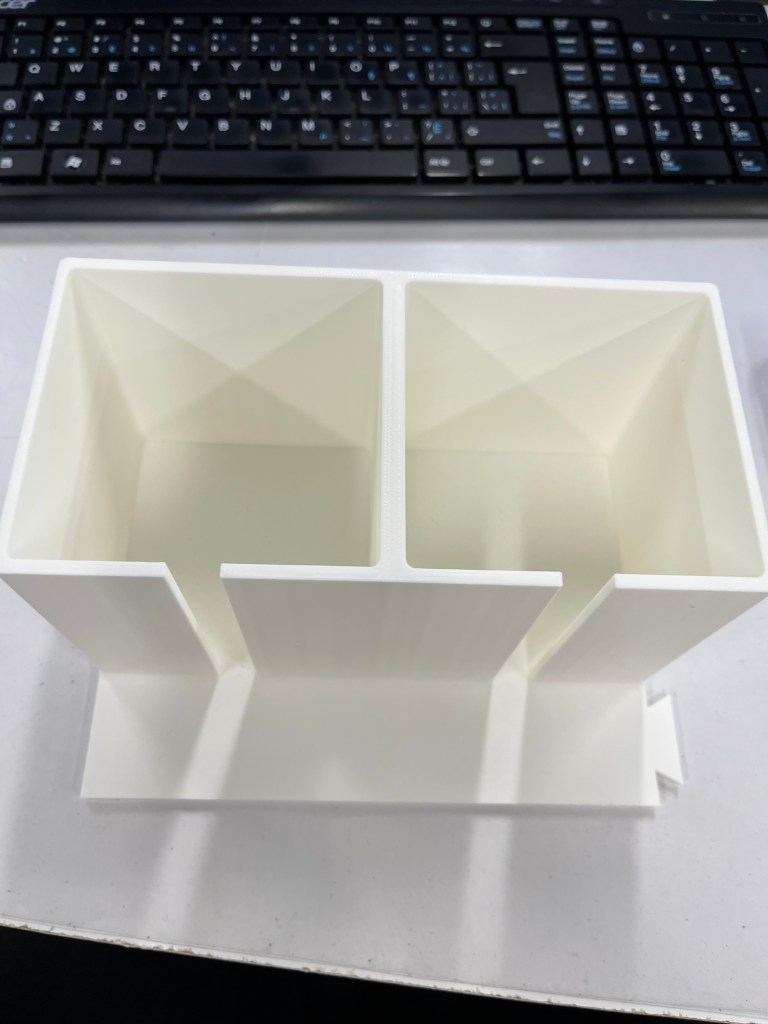

One of the production managers asked me to help come up with a way to prevent chemical spills at a small workstation where a high-temperature solder pot is used. After soldering, wires are dipped into three different chemical cups, but because the space is confined to a small cubby, those cups have been knocked over in the past.

I designed a jar holder with a wide base that securely fits the cups and helps keep everything stable. I 3D printed the holder using PLA, but since the printer’s build plate wasn’t large enough for all three cups in one piece. I split the design into a one-cup and a two-cup sections that could be connected using a puzzle-style joint.

Since putting it in place, the holder has completely stopped spills and made the workspace feel a lot safer and more manageable for the team.

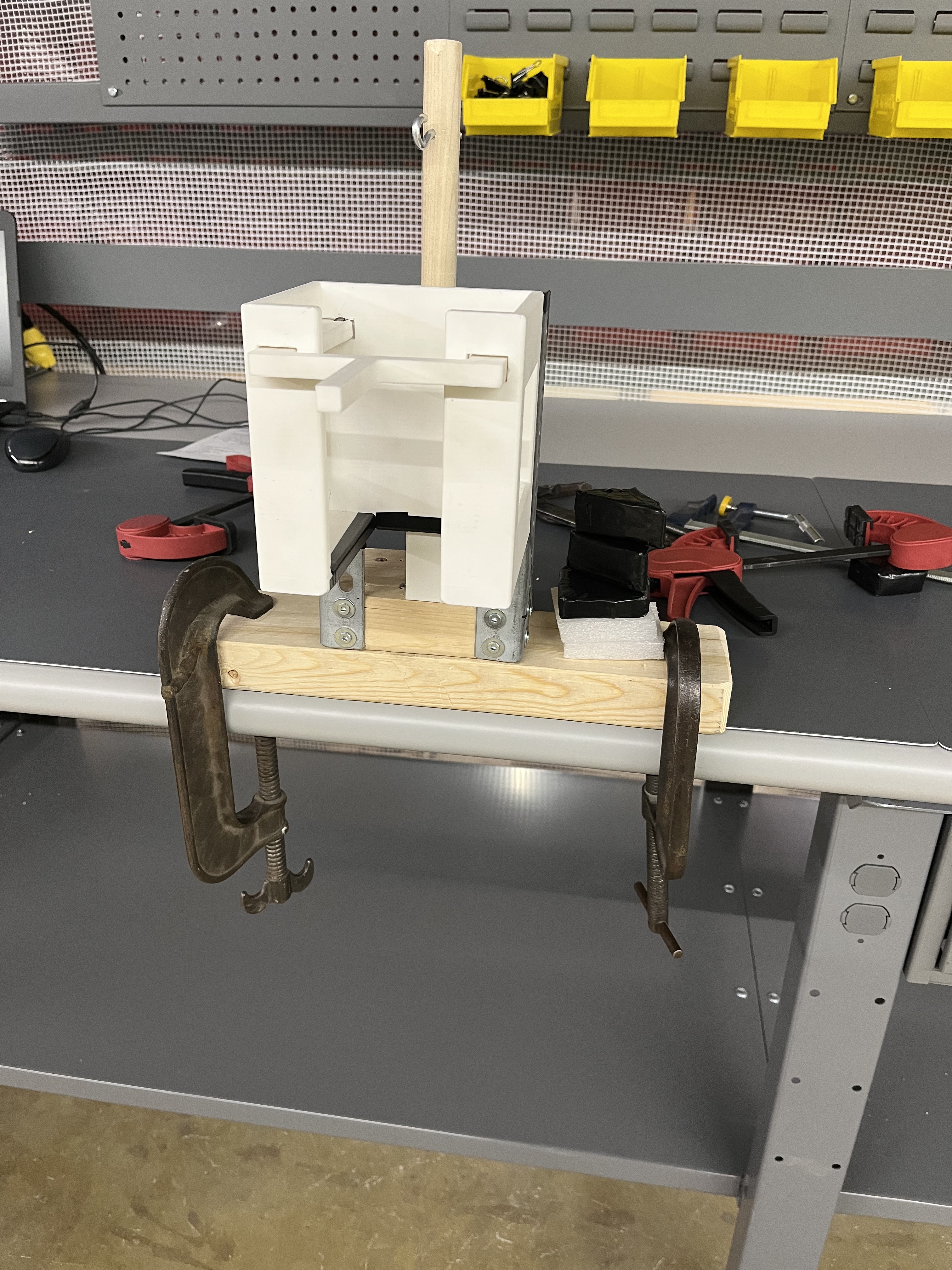

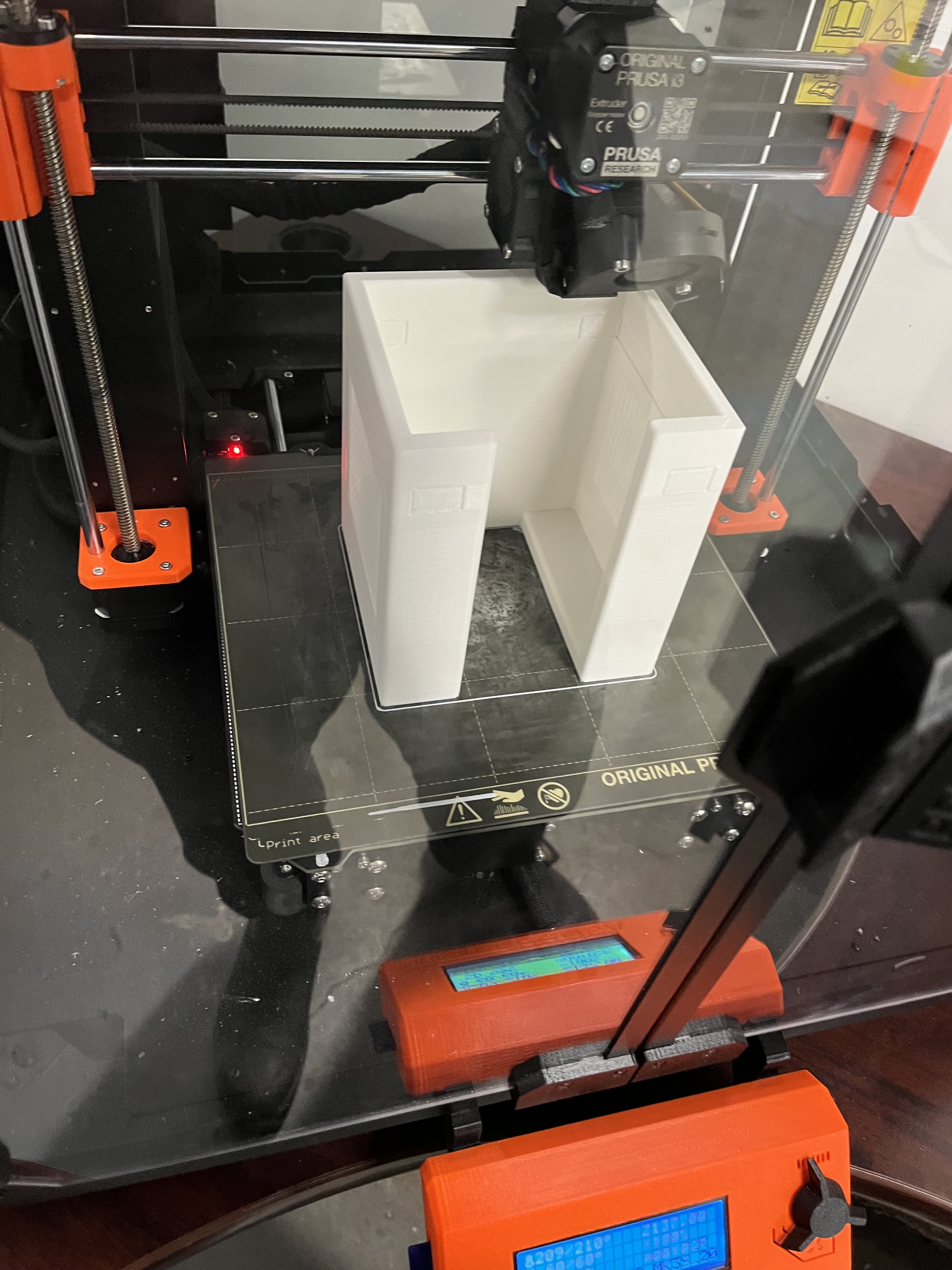

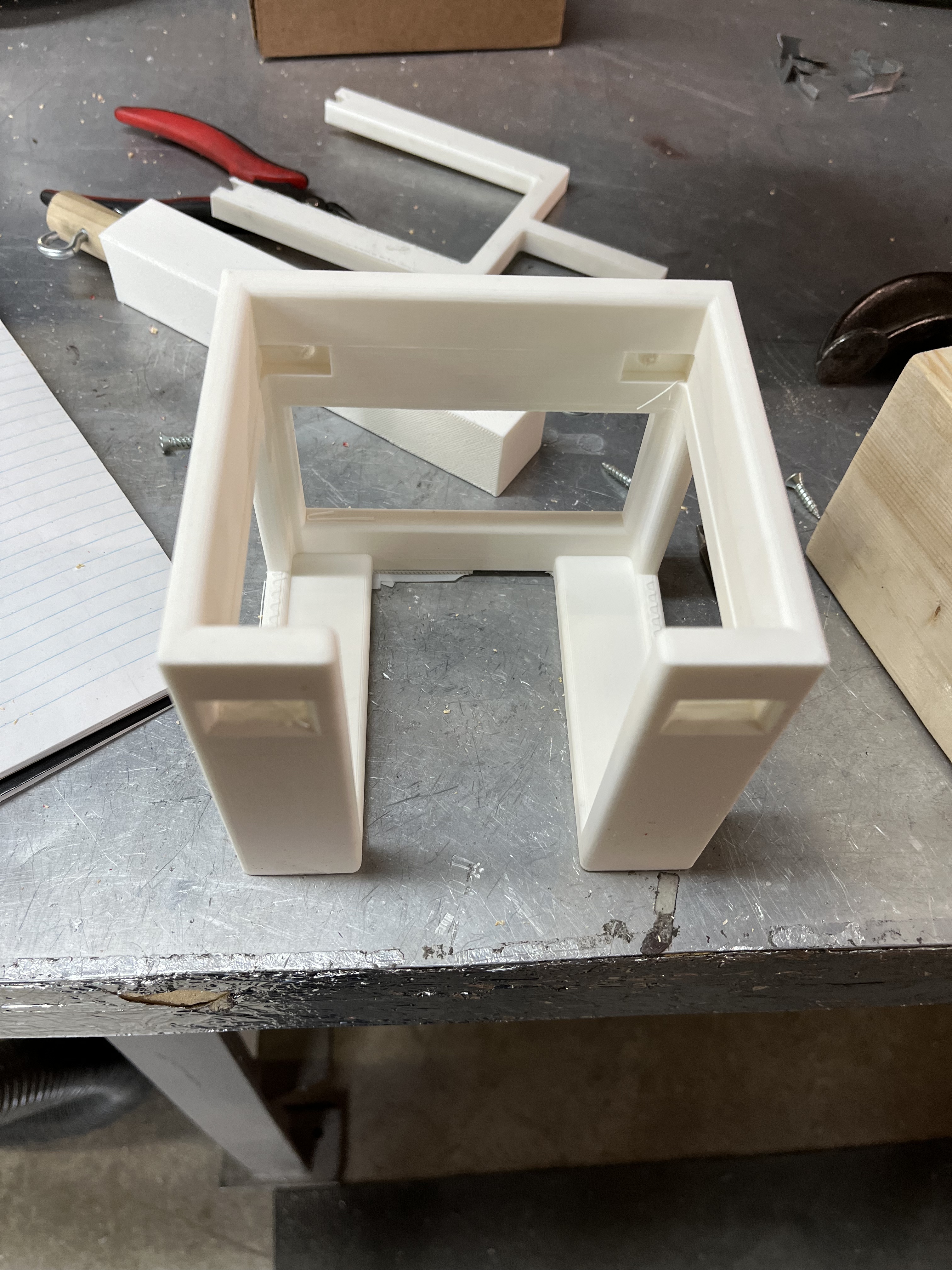

Transformer Wrapping Jig

Jan 2025 – Feb 2025

I was tasked with developing a tool to assist production workers in wrapping wire around a core for a specific transformer order. The jig I designed elevates and secures the part, allowing workers to thread the wire through the top and bottom efficiently. A telescopic end holder ensures the wire is anchored at a precise distance to meet length specifications.

Initial iterations faced challenges with the telescopic holder and sliding fork height. To address this, I redesigned and reprinted the main body to fit size requirements. Additionally, since multiple part sizes needed to be accommodated, I implemented adjustable levelers to modify the box height for a secure fit. The main components, including the box, telescopic holder, and levelers, were 3D printed from PLA, while the holder shaft was crafted from scrap wood. Other structural elements were machined from repurposed materials.

Ultimately, this jig reduced the wrapping process time from 8 minutes to 5, improving efficiency and workflow.

-

Final product

First iterations/prototypes for the jig

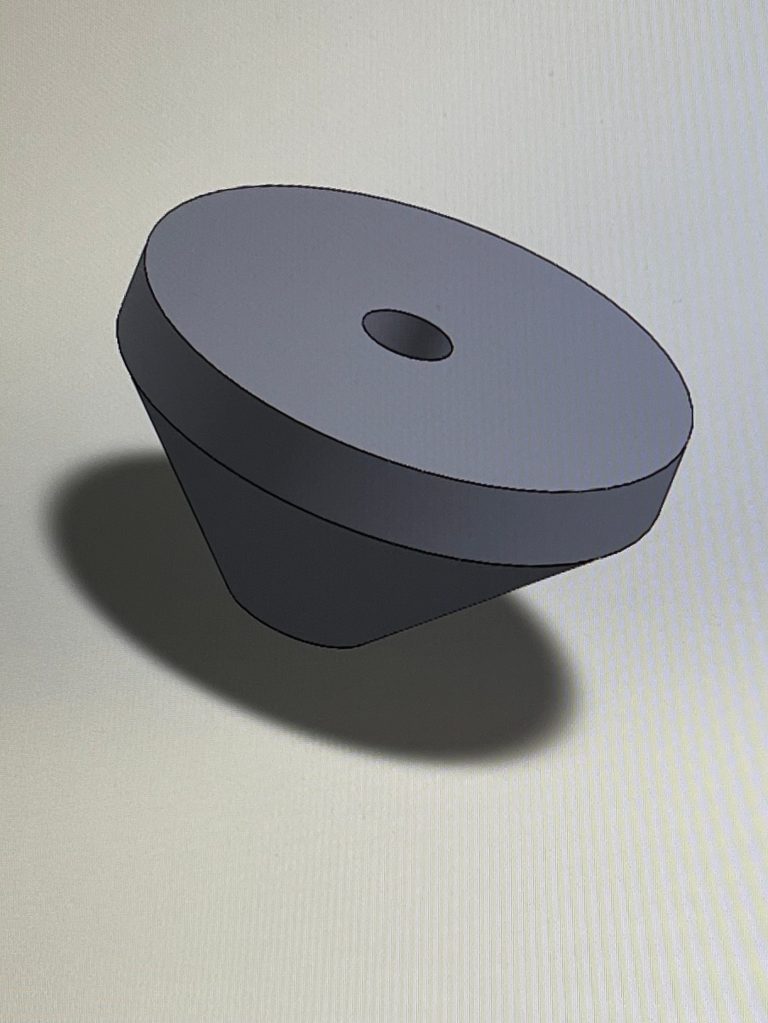

Spool Cap Tightener

Jan 2025 – Jan 2025

While working on the “Wire Salad Spinner” project, I ran into an issue where the wire spool would shake and shift as it unwound. This added extra tension to the wire, making it harder for the tool to pull the wire smoothly.

To solve this, I designed a spool tightener using a truncated cone with internal threading that fits snugly into the center of the spool, securing it to the turntable. This helped stabilize the spool and made the unwinding process much smoother and more consistent.

The tightener ended up being a simple but effective fix for any future wire unwinding or cutting tasks as well.

Wire “Salad Spinner” Jig

Jan 2025 – Jan 2025

As one of my first projects at Velatron, I was tasked with improving the wire-wrapping process for production. The original method required unwinding wire from a spool and manually rewrapping it, leading to inefficiencies such as tangling and the wire touching the ground. The goal was to create a system that produced neatly wrapped, tangle-free wire with consistent lengths.

In the initial design, I 3D-printed a cylindrical device with a sliding shell. The wire was wound by spinning the cylinder on a turntable connected to the spool. Once wrapped, the sliding shell was removed to release the coiled wire, which was secured with a zip tie. However, this version had flaws: inconsistent wrapping angles resulted in variable lengths, and the mechanical counter failed to reliably track rotations.

After multiple prototypes and iterations, I developed a more reliable solution. Using SOLIDWORKS, I designed a threaded sliding ring with ridges to guide the wire for precise, consistent wrapping. Visual markers on the cylinder replaced the error-prone counter system, allowing workers to wrap at predefined points. This simplified the process and eliminated inconsistencies.

The final design reduced the wire-wrapping time from 8 minutes to 3 minutes per unit, significantly improving efficiency for high-volume production and saving valuable time for the team.

-

Final Product

First iterations

Wire Wrapping Visual Indicator

Jan 2025 – Jan 2025

My first manufacturing project addressed an issue on the production floor where a worker struggled to gauge the required wire lengths for transformer winding.

As an initial solution, I created a “flag” using scrap plastic, an aluminum rod, and electrical tape. This device was intended to slide into the part’s holes, acting as a visual marker to guide the worker during wire wrapping. However, the design proved ineffective because the steel jig used in the production process prevented the aluminum rod from fitting properly, making the flag unusable.

In the final iteration, I 3D-printed a custom jig that wrapped around the part instead of relying on its holes. This design included an adjustable set screw, allowing it to be secured at various angles while remaining compatible with the production jig.

This project not only introduced me to 3D printing, which I now use extensively, but also highlighted the importance of maintaining open communication with production workers and managers to better understand their needs and challenges.

-

Final Product

First prototyppe – The Flag